RUTILEA, Inc. (Head office: Kyoto, Kyoto Prefecture, Japan; President: Takafumi Yano) has been published in Image Lab Vol. 35 Jan 2024 (Publisher: Nippon Kogyo Shuppan).

■Publishment: Image Lab Vol. 35, Jan 2024.

■Publisher: Nippon Kogyo Shuppan

■Special issue: The forefront of automatic visual inspection & machine vision technology ①

■Article: AI-based defective image generative technology (p. 85~88)

■Writer: Masao Shinzaki, Project Manager, Business Division, RUTILEA Inc.

Please see the article below.

AI-based defective image generative technology

Writer

Masao Shinzaki

RUTILEA Business Division

Introduction

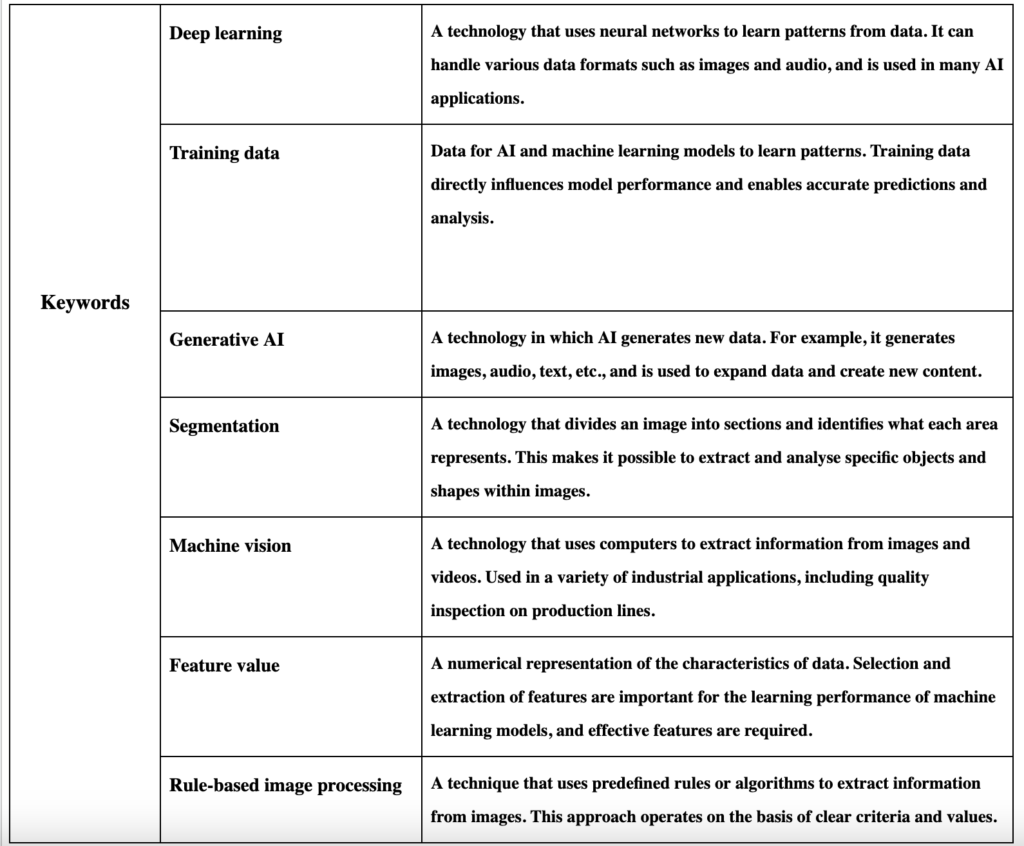

Techniques such as segmentation, reading, and classification using deep learning are used in industrial machine vision. In areas such as visual inspection they are quite prominent. These technologies extract features from image data, providing clear details of the product. They are being developed further, and progress is being made in overcoming problems that were difficult with conventional rule-based image processing.

One issue when utilising deep learning is that a large amount of image data is required during the learning process. Without sufficient training data, the accuracy of AI cannot be guaranteed and inspection accuracy may decline as a result. Therefore, in many cases, a large amount of image data is required in an inspection process using image processing.

Challenges in preparing large numbers of images

One of the challenges when preparing large amounts of image data is that it increases human and time costs. Finding ways to reduce these costs and efficiently collect high-quality data is the key.

There is a method to collect data by photographing the actual product and the environment around it, but this method is time and cost intensive. Furthermore, specialised knowledge and equipment are required to ensure high-quality data. It takes time to process and confirm the quality of the data.

Another method is image generation using optical simulation. This method simulates the movement of light and generates an image of a virtual scene, with realistic light reflections and bends. It is possible to generate images that take various conditions into consideration this way, and it is possible to efficiently prepare images under various conditions. However, setting up simulations and adjusting parameters requires specialised knowledge, and it is difficult to completely reproduce the real environment. It's not an easy task. Therefore, in some environments and conditions, there may be differences from the actual image.

Generation of good and defective images using generative AI

To address the above-mentioned problems, a method for generating good and defective data using generative AI is introduced. It can do so rapidly. Specifically, the AI model is trained on the characteristics of good and defective products to be generated. The use of AI-generated images can be applied to various cases of defective products that do not actually exist. The ability to prepare and respond in advance to future products is expected to improve production line utilisation rates. It means that quality control can be more flexible and efficient in the process, which also contributes to the reduction of production costs.

In addition, Generative AI technology is evolving rapidly, making it possible to generate images with even higher accuracy. For example, by utilising advanced technologies such as Stable Diffusion, very realistic images of good and defective products can be generated, with a quality that is indistinguishable from the actual product.

Software

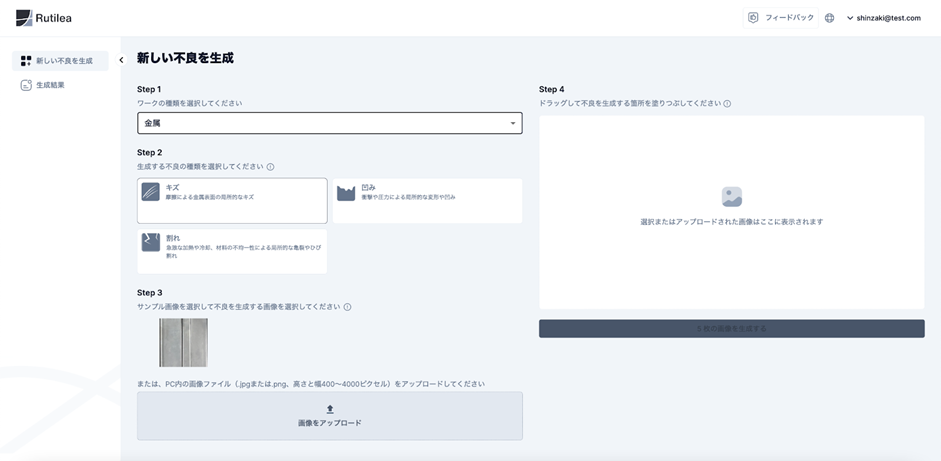

RUTILEA introduced a defective image generative AI service to address the above-mentioned problems and introduced ways to utilise it in industry. On the main screen of this service (Fig. 1), the user initially selects the desired workpiece and type of defect from the options (A).

Figure 1: Main screen of the defective image generative AI

|

Type of workpiece |

Type of defect |

Description |

|

Metal |

Scratch |

Localised scratches on metal surfaces due to friction |

|

Crack |

Localised cracks and fissures due to rapid heating or cooling or material inhomogeneity |

|

|

Indentation |

Localised deformation or indentation due to impact or pressure |

|

|

Screw |

Head scratch |

Flaws in screw heads |

|

Neck scratch |

Scratches on screw necks |

|

|

Front manipulated |

Bent, crushed or missing screw tips |

|

|

Top thread |

Localised scratches on the upper surface of the screw's helix |

|

|

Side thread |

Localised flaws on the lateral side of the screw's helix |

|

|

Food |

Insect |

Small insects on food |

|

Capsule |

Crack |

Cracks on the capsule surface |

|

Imprint |

Misprint of the text |

|

|

Scratch |

Scratches on the orange part of capsule surface |

|

|

Poke |

Broken holes in capsule surface |

|

|

Pill |

Color |

Different pigments on the tablet surface |

|

Combined |

Random among pigmentation abnormalities, debris contamination and scratches |

|

|

Contamination |

Fragments of other pills on the main pill |

|

|

Scratch |

Scratches on tablet surface |

|

|

Plastic |

Scratch |

Localised scratches on plastic surfaces due to friction |

|

Crack |

Localised cracks and fissures due to strong pressure or plastic degradation |

|

|

Foreign substance |

Foreign bodies on plastic surfaces |

|

|

Chipping |

Chipping of parts of the plastic due to impact |

Table 1 Available types of workpieces and defects to be generated

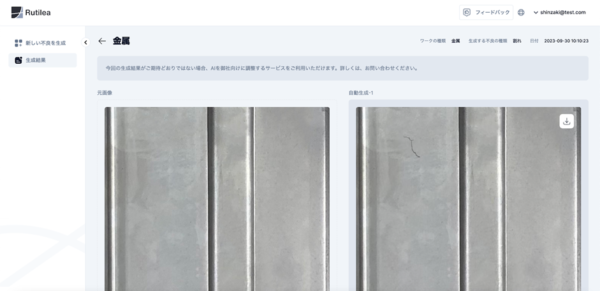

Figure 2: Detailed results screen of the defective image generative AI service

Next, in the image selection section (B), the user can either utilise the sample good image data provided by the service or select one from data prepared by the user himself. The user then utilises the paint tool (C) to start the process of generating a defective image by filling in the areas where they would want to generate defective parts. Once the generation is complete, the user can check the generated defective images on the generation results page (D).

(A) The workpiece type and defect type options provide a wide range of examples so that many users can select examples of defective images to be generated without any difficulty (Table 1). This allows the user to start the generation process without hesitation. The training of the Generative AI for these types of image generation has already been accomplished.

(B) In the image selection section, even first-time users can select which good image data they would like to use. It is easy to understand how to prepare the data, and the user can use the specific good image data they wish to use. The images can then be customised to produce a customised defective image.

(C) The paint tool has a very simple interface and can be used to generate defects in any area. The system is designed to allow users to intuitively choose what is best for them.

(D) On the generated results page, the generated defective images are displayed in tabbed format and can be viewed at a glance. If multiple defective images are generated, each image result can be quickly and easily identified and accessed. The system is designed to enable users to efficiently manage and utilise the image data generated. It is also possible to check the details of individual results. (Fig. 2)

Conclusion

This article introduces the striving image processing technology using deep learning, which has begun to be actively used in inspection processes at manufacturing sites. We focused on training data issues that require large amounts of image generation. As a solution to the mentioned problems with such developments, RUTILEA proposes a training image generation technology and defective product image generative AI service.

The evolution of generative AI technology is expected to improve the accuracy and efficiency of the inspection process, reducing the workload of inspectors.Through this, it will become possible to realise a society that considers the sustainable development of the manufacturing industry.