Overview

In cases where the cost of robots is too high to invest (for reasons such as low quantity but high variety production or complex workpiece shapes), the introduction of an inspection support system using ImagePro can improve the efficiency, standardization, and traceability of visual inspections.Challenge

・When inspection workpieces are of complex shapes, it could be difficult to see defective parts with raw eyes plus the burden on both the human eyes and shoulders. In addition, the cost of introducing AI automatic inspection is high which cause the issue for production sites when the return on investment does not match the cost.

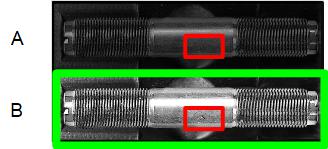

・Defects that are difficult to detect by visual inspection can be found more quickly by applying multiple image filters.

Image B: the contrast in Image A is enhanced to make

the scratches more visible

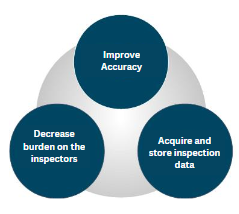

Benefits

Solutions

Inspector operating with the Inspection Support System

How to Use

Place the workpiece is on the inspection stand. The inspector checks for defects on the monitor. The image is saved the moment when a defect appears on the screen.Inspectors' Voices

“Now that we can check with an enlarged image, it's definitely much easier to see!”

“My eyes don't get tired easily anymore!”Comparison with full automation

At production sites where replacing visual inspections with AI is difficult in the immediate future, the software adaption to visual inspection is often an effective approach.

Place the workpiece is on the inspection stand. The inspector checks for defects on the monitor. The image is saved the moment when a defect appears on the screen.Inspectors' Voices

“Now that we can check with an enlarged image, it's definitely much easier to see!”

“My eyes don't get tired easily anymore!”Comparison with full automation

At production sites where replacing visual inspections with AI is difficult in the immediate future, the software adaption to visual inspection is often an effective approach.