Overview

Visual inspection on the wear condition of cutting tools could be time-consuming. We provide an AI solution that standardize the inspection of cutting tools and further achieve the outcome of reducing the cost of re-sharpening the tools.Challenge

It is labor-consuming to inspect cutting tools.

There is no clear inspection standard. Depending on individual judgement, the cutting tools that are still in usable condition could be send to maintenance which creates additional expenses.

The necessity to collect useful data and to organize images and cutting tools by IDs for future operation improvement.

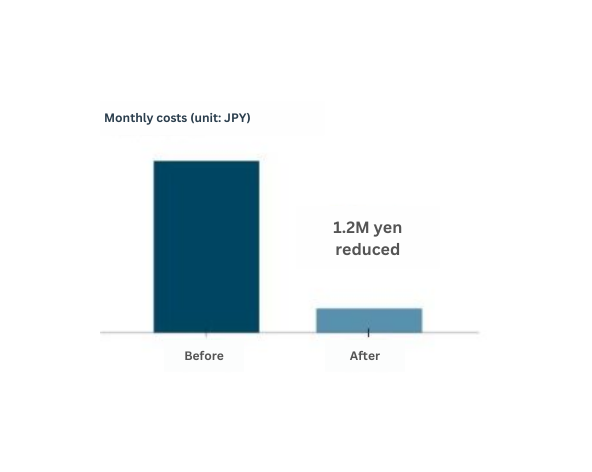

Benefits

Effect of reducing 1.2 million yen of costs per month after implementation

Solutions

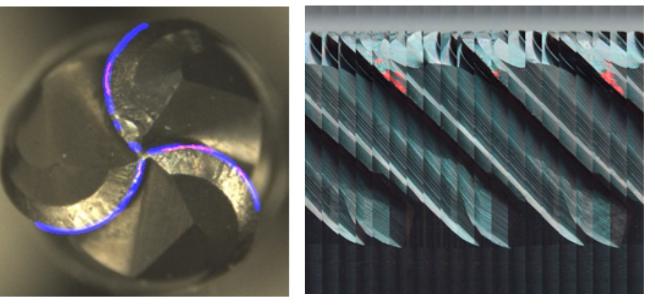

An auto-focus camera is used to photograph both full front and side of the cutting tool. For each image, we apply semantic segmentation to detect areas of wear. The SCARA robot proceeds to sort the tools by their OK/NG judgement results based on the predefined inspection criteria. The judgement result and image data is saved to be apply to cutting tool usage improvement. In the future, we plan to expand the system with digitalized purchase function that automatically places orders to resharpen the tools.

Inspection Equipment

Blade edge section (blue),

wear area (pink)

Wear area (red)