Overview

Developed inspection equipment capable of inspecting with the same speed and accuracy as human inspectors.It is a high-return investment and a major step towards factory automation.

Challenge

Visual inspections are physically demanding for inspectors, and the inspection results are highly variable.

Benefits

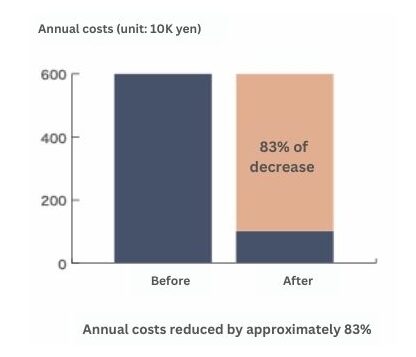

・Successfully reduces annual costs by approximately 83%

Solutions

・Succeeded in automating a series of processes from transportation to inspection of the workpiece by cooperating robots and AI inspection equipment.

・Taking images of the defective area is now possible

Figure 1. and Figure 2.: Poor Polishing (surface reflectance is measured: judged by rule-based method)

Figure 3. Scratches (surface pattern and scratches: judged by AI anomaly detection)

Figure 4. Contamination (Foreign matter in hole: judged by AI abnormality detection)